Table of Contents

4 Reasons to Use Gas When using Fiber Laser Cutting Machine

As a general processing method in modern manufacturing, laser cutting machine breaks the traditional processing method and is widely used in all walks of life with a brand-new cutting method, especially fiber laser cutting machine, which has developed rapidly in recent years.

Fiber cutting is achieved by instantly vaporizing the sheet by laser high temperature, which is with the auxiliary gas blowing out the vaporized sheet slag at the same time, and completes the cutting process of the sheet with the mechanical movement of the machine.

Users who understand fiber laser cutting machines must have know that auxiliary gas should be used in fiber cutting process. This is why many people are more concerned about the issue of “gas”.

So, today MORN Laser will take you to learn about why the auxiliary gas is added to the fiber laser cutting machine in the cutting process and how users can use the auxiliary gas properly. Before figuring out how to choose auxiliary gas, it’s important to understand why the auxiliary gas is used and the role of the auxiliary gas.

Why Adding Auxiliary Gas

Why adding auxiliary gas when fiber laser cutting machine is cutting metal materials? There are four reasons:

1. Strengthen Original Metal Plate

Allow the auxiliary gas to chemically react with the metal material to increase the metal plate strength.

2. Puff away Slag

Help the equipment blow away slag from the cutting area and clean the cutting seams.

3. Cool the Adjacent Area

Cool the adjacent area of the slit to reduce the size of the heat affected zone.

4. Protect the Focusing Len

Protect the focusing lens and prevent combustion products from contaminating the optical lens.

How to choose auxiliary gas

When the fiber laser cutting machine cuts metal plates, three types of gases, nitrogen, oxygen, and air can be selected as auxiliary gases. Their functions are as follows:

1. Nitrogen

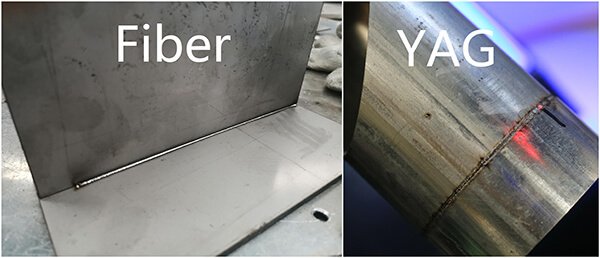

When cutting stainless steel or aluminum, nitrogen is selected as an auxiliary gas, which can play a role in cooling and protecting the material. After cutting, the section of cutting metal is brighter and the effect is good.

2.Oxygen

When cutting carbon steel, oxygen should be used. Because oxygen has the function of cooling and accelerating combustion and speeding up cutting. The cutting speed is the fastest of all gases.

3.Air

In order to save costs, you can use air to cut stainless steel, but there are fine burrs on the reverse side, just sand it with sandpaper. This means that when the fiber laser cutting machine cuts certain materials, air can be selected as the auxiliary gas. When using air, you must choose an air compressor. If you want to use air, please contact our company MORN Laser to install an whole system of air cooler, dryer and filter before using it. Otherwise, it will cause irreversible damage to the laser head. The air compressor pressure must be at least 16 bar.

Many gases can be used generally. The important thing is to consider the cutting cost and product requirements, such as cutting stainless steel materials. When the requirement of product quality or surface cut quality is not very high, such as the process that it needs to go through painting and other processes. In the metal fabrication process, air can be used as the cutting gas, which can reduce a lot of costs.

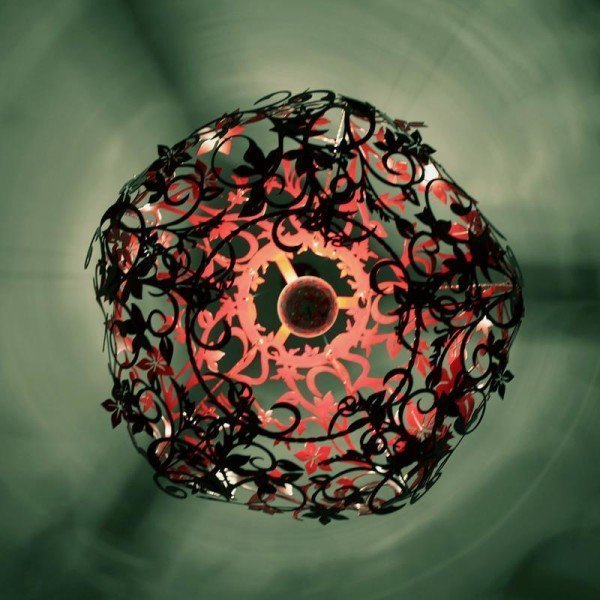

When the cut product is the final product, and there is no subsequent process, it is necessary to use protective gas, such as craft products. Therefore, in the cutting process, the gas must be selected according to the characteristics of the product.

Our company is committed to providing customers with professional and reliable high-quality laser equipment. Before purchasing the machine, we will have a detailed understanding of your needs, and then recommend the appropriate power and configuration. Professional team do professional work. For more machine details, please visit our website: http://www.morntech.com/fiber-cutting/