Table of Contents

The advantages of the exchange table laser cutting machine compared with other products

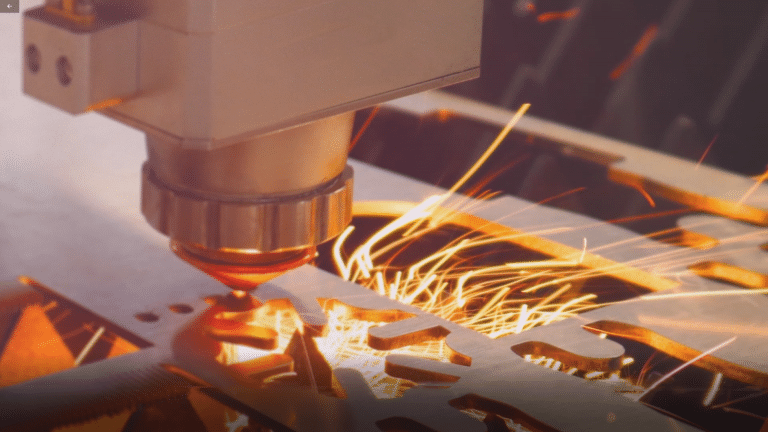

The cutting principle used by the Exchange Table Laser Cutting Machine is a high-performance laser cutter. During the cutting process, the laser emits countless high-performance, high-energy laser rays. The huge energy generated by these laser rays can be instantaneous Vaporize the cut surface so that the very hard interface can be easily removed. At present, this process is still an advanced cutting process, no other cutting process can surpass it, and this cutting process is very fast in the cutting process, and it can easily cut very thick steel plates in an instant. The accuracy is also very accurate.

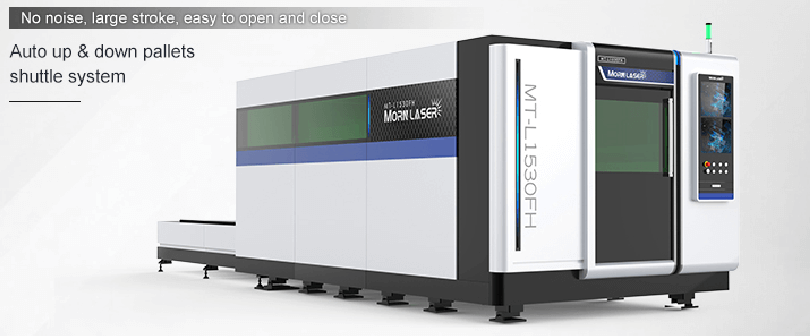

As shown in the figure below, the left is the exchange table, and the right is the surrounded exchange table. The right side is responsible for cutting, and the left side is responsible for feeding. It will be very convenient, efficient, and time-saving.

The exchange table cutting machine adopts a gantry double-drive structure, the bed is an integral weldment, a fully enclosed structure, with a double exchange work platform, the Z axis is light in weight, and the dynamic performance is good. Both are rough processed after annealing and subjected to secondary vibration aging treatment. Afterwards, the overall finishing is performed to obtain extremely high geometric tolerance accuracy.

The main frame of the fixed workbench: adopts the overall bending process of ultra-thick plate, and then integrally welds to form; thus, it has a great bearing capacity.

Cutting table: It is welded by the whole square pass, and each node is made of ultra-thick keel to ensure long-term use, the bed does not collapse, and the structure is stable;

The following introduces the advantages and characteristics of fiber laser cutting machine with exchanged table compared with other similar products:

1. The mechanical operation process is very convenient

In the process of using the switchboard laser cutting machine, all information and energy transmission are transmitted through optical fibers. The advantage of transmitting in this way is that it saves a lot of manpower and material resources. Any light path leakage will never occur.

And without any optical path adjustment before using the equipment, energy can be easily transferred to the laser.

2. The cutting performance is very stable

In the cutting process of this kind of laser cutter, a very stable laser is used. The service life of this kind of laser will be as long as several years, and in the process of use, there is almost no system failure except for human factors damage. Precisely because of this, even though this fiber laser cutting machine with exchange table is under long-term working pressure, it will not produce any vibration or other adverse effects.

3. The volume of the machine itself is small

This kind of laser cutter has only one core component, that is the laser emitting laser source. And, if campared with the other cutting products of the same type, the volume of this laser source is very small and does not occupy a lot of space, so the overall volume of the machine will be reduced. It is much smaller, whether it is in the process of mechanical production or transportation, it can reduce a lot of manpower and material resources for us.

At present, most of the lifting tables are hydraulically driven, and the four corners of the lifting platform are driven by hydraulic cylinders to realize the up and down movement of the lifting platform.

There are some shortcomings in the actual use of hydraulic lifting table:

①Poor synchronization, especially when somewhere is partial load, the problem of asynchrony becomes more serious;

②The cost is high and a special hydraulic station is needed to provide hydraulic oil;

③The running smoothness is not good, and there will be a big impact when starting and stopping;

④ The positioning accuracy is not high. The position deviation of the upper and lower limit point stops is large.

In response to the above problems, we adopted the design of high and low double exchanged tables. The structure of the high and low tables is simple and can be exchanged quickly and smoothly. The exchange time can be completed within 15 seconds. The fast exchange of the workbench can greatly reduce the workbench exchange time and improve work efficiency.