Table of Contents

How to choose a laser cutting machine?

In order to choose the right laser cutting machines according to your requirements, you first need to choose according to the main characteristics of the material to be cut. To cite a few examples, not all metal cutting machines, plastic cutting machines, cloth cutting machines, and wood cutting machines use the same technology.

You also need to select a machine that is calibrated according to the thickness to be cut and a worktable whose size is suitable for the part to be cut. Finally, choose the cutting technique based on the accuracy you need, the quality of the cut, and the desired productivity.

What are the main types of cutting technology?

To cut metal, you can choose laser cutting, plasma cutting, EDM, or oxyacetylene cutting. For rigid materials, metal materials, or other materials, water jet cutting can be used, which can cut thicker materials. If you need to cut softer materials, such as cloth, leather, soft plastic, paper or cardboard, you can choose knife cutting.

Under what circumstances to choose a laser cutting machine?

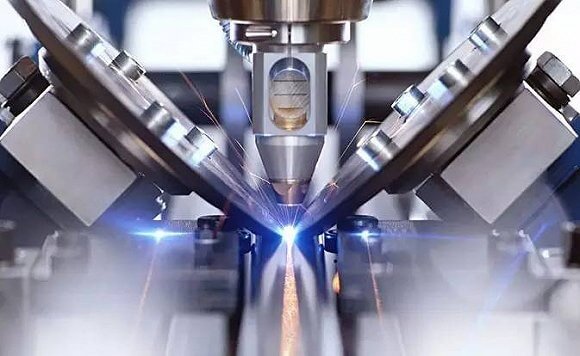

Laser cutting machines use the heat emitted by a laser beam guided by a mirror or optical fiber. Depending on the type of laser, different types of materials can be cut.

CO2 laser cutting machines are generally used to cut plastic, foam, wood, glass, textiles, or mild steel. The CO2 laser cannot cut reflective metals such as copper or brass.

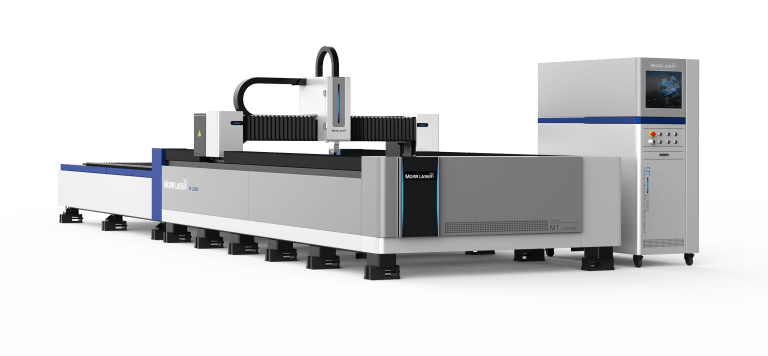

The more powerful fiber laser cutting machines are specially designed for cutting metal plates, steel, stainless steel, aluminum, and some plastics. Laser cutting can cut different materials just by setting the laser parameters without changing tools. This is a very precise process, with a very small notch width, which can achieve complex contours. Depending on the material to be cut, the cutting speed can be very fast. The laser cutting machines are fully automatic and almost do not require manual intervention, which greatly limits the risk of accidents. The main limitation of laser cutting is that its shallow cutting depth is approximately 25 mm. Therefore, the main application of laser cutting in the manufacture of metal plates (especially in the automotive industry) and frames (used in electrical cabinets, computers, etc.). For workpieces with a thickness of more than 25 mm, plasma cutting is the most suitable method. The area heated by the laser beam is not very large, but because the temperature rises sharply, great deformation occurs. Laser cutting will produce gas emissions, so you must ensure that the room where the cutting machine is located is well ventilated.

When to choose a plasma cutting machine?

The plasma cutting machine is only suitable for ferrous metals (steel, stainless steel, etc.) and non-ferrous metals (brass, copper, aluminum, etc.) with a maximum thickness of 160 mm. For thicker plates, plasma cutting is faster than laser cutting, and for medium-thick plates, plasma cutting is faster than oxyacetylene cutting. Generally speaking, plasma cutting is suitable for cutting thick metal sheets. The principle of plasma cutting is relatively close to the principle of TIG welding: an arc can be generated to ionize the gas sprayed through the nozzle between the electrode and the workpiece to be cut. Plasma cutting usually uses air, gas, nitrogen, oxygen or hydrogen. Regardless of the gas used, the nozzle and electrode need to be replaced regularly. The portable plasma cutting machine can be used on site. Due to the heat generated and the fumes from vaporized metal, plasma cutting can only be performed in well-ventilated areas or outdoors.

When to choose a waterjet cutting machine?

The waterjet cutting machine uses water pressure to cut all types of materials (except for tempered glass, which will shatter under pressure), with a thickness of up to 600 mm. However, we recommend limiting the cutting of workpieces with a thickness of no more than 200 mm in order to maintain the correct cutting speed and accuracy with this method. For soft materials, either material cut by a knife or pure water can be used. However, for harder materials, a liquid made of water containing abrasives is required. For softer materials, no abrasive can extend tool life. Water jet cutting will not deform the workpieces (it will not deform due to temperature rise), and the cutting edge will be soft and shiny. However, the cutting process is very noisy. Cutting in a straight line can be relatively fast, but when the direction changes, the cutting speed will drop sharply. The cost of purchasing a waterjet cutting machine is relatively high, but it is still cheaper than a laser cutting machine

When to choose an oxyacetylene cutting machine?

The oxyacetylene cutting machine sprays pure oxygen onto the molten metal for cutting. This technique can only be used for certain types of steel, but its advantage is that it can cut steel plates up to 400 mm thick. This is a relatively slow process, but some machines integrate multiple oxyacetylene cutting torches, which can be run in parallel to increase productivity.

When to choose an EDM cutting machine?

An electric discharge cutting machine, also known as an electric discharge erosion machine, is used to process conductive materials. They can make very precise cuts on parts with a maximum thickness of 300 mm. The principle is to remove material from the workpiece by electric shock. It is recommended to use this process to cut very hard metals, such as hardened steel.

When to choose a knife cutter?

The knife cutter can cut soft materials up to 50 mm thick, such as cloth, leather, vinyl, etc. For larger thicknesses, it is best to choose a water jet cutting machine. This technology can perform high-precision cutting but requires regular tool (knife) replacement. This process can also be used for packaging materials such as paper and cardboard.