Table of Contents

5 Essential Elements For Fiber Laser Cutting Machine

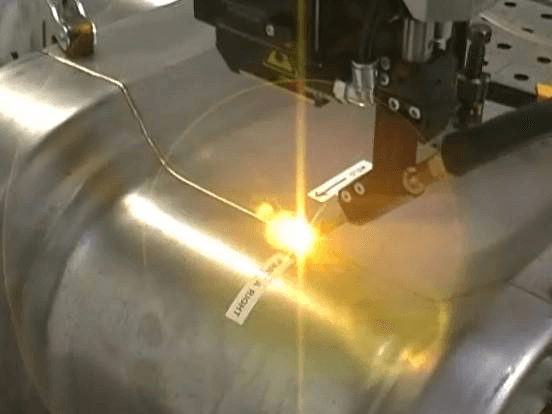

The fiber laser cutting machine is to focus the laser light emitted from the laser into a high-power density laser beam through the optical path system. The laser beam irradiates the surface of the workpiece to make the workpiece reach the melting point or boiling point, and the high-pressure gas coaxial with the beam blows away the molten or vaporized metal. Friends who have known laser cutting machines should know that the core component of laser cutting machines is lasers. With the continuous development and progress of conversion science and technology, lasers are now pumped by YAG lamps, to medium and small power CO2 lasers, and then to the present. The 20,000 watt fiber laser developed by Han’s Laser continuously promotes technological innovation. The laser plays a decisive role in the cutting effect of the laser cutting machine.

The quality of the laser cutting machine affects the cutting quality of the laser cutting machine. At present, the CO2 laser cutting machine is mainly used for cutting non-metal materials, and the fiber laser cutting machine is mainly used for cutting metal materials. They use different solids or gases as media.

Five factors that determine the cutting quality of a laser cutting machine

- Excitation method. Carbon dioxide laser is a laser that uses electrodes to excite carbon dioxide gas. According to the orientation of the metal electrode, it can be divided into direct current excitation and radio frequency excitation.

- Laser frequency. Pulse frequency mainly affects cutting speed and cutting roughness. To obtain high-speed cutting, high frequency is necessary. Most manufacturers now produce carbon dioxide lasers with frequencies below 5000 Hz.

- Beam divergence angle. The beam divergence angle is not part of the laser components, but because the laser method has a great influence on the far-field divergence angle, the influence of the beam divergence angle on the cutting quality is reflected in the width and slope of the interception. The smaller the divergence angle, the narrower the intercept width, the smaller the slope, and the higher the quality.

- Laser method. Laser methodis one of the important goals of measuring laser quality. It can be divided into single mode, base mode and multimode. The basic mode is the TEM-00 mode, and the index on the X and Y axis is 0, so it is an ideal point. The beam diameter can be obtained by using a TEM-00 mode laser, and because of the small spot size during the cutting process, a cut is obtained and the cutting speed is faster. Multimode is a non-zero index in the XY direction, and its beam quality is poor, and it is usually only used for welding and not necessarily for cutting.

- Laser power. Laser power includes peak power, energy stability and other factors. It is possible to cut sheets of different thicknesses with different power. For example, a 4KW laser can cut 20mm thick carbon steel plate, or 15mm stainless steel, 10mm aluminum alloy; a laser above 5KW can cut 25mm thick. Carbon steel, stainless steel up to 20mm. Long-term production is also a very important test for lasers.

The above five common factors determine the cutting quality of your choice of laser cutting machine, so a good machine must not only care about the price, it must be compared with the configuration to be desirable.Those who are engaged in the production and processing of laser cutting equipment know that cutting accuracy is an important part of judging the quality of a machine, and newcomers should pay attention when buying equipment. In fact, the accuracy of the laser cutting machine does not entirely depend on the laser cutting machine itself, but is composed of many factors.