It is not ending when you receive our laser cutter machine. The stability of the machine to work properly, and the usual proper operation and maintenance are inseparable.

This post provides details for routine maintenance and winter maintenance of your CO2 laser cutter. Those are important matters you should notice when operating such a laser tool. Follow these steps to maintain your laser cutter in a proper way to extend the stability and service life of the tool.

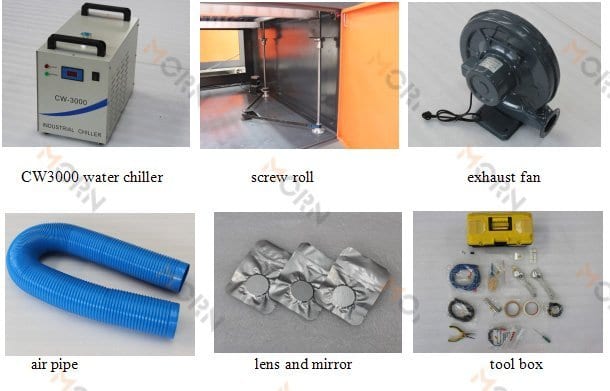

Mainly contents are as follows:

- Daily maintenance of CO2 laser cutter

- The change of water and water tank cleaning (recommend clean water tank and replace circulating the water once a week)

- The cleanness of the fan

- The lens cleaning (advice before work every day, clean equipment was turned off)

- Winter maintenance of CO2 laser cutting machine

Table of Contents

Daily maintenance of CO2 laser cutter

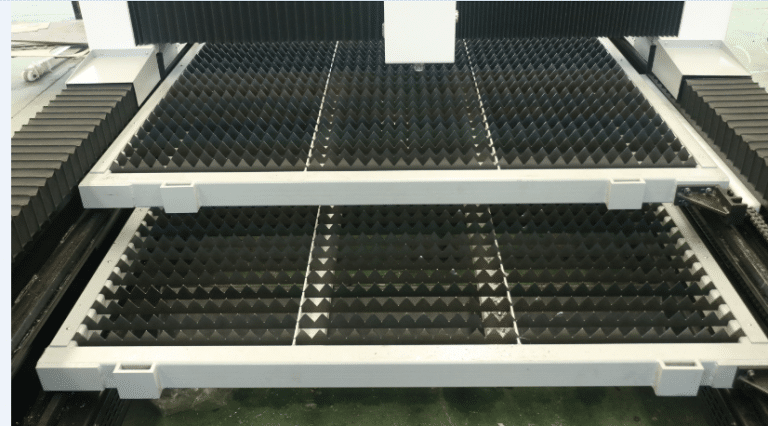

1. The change of water and water tank cleaning (recommend clean water tank and replace circulating the water once a week)

Note: the machine work before must ensure that the laser tube is full of circulating water.

Circulating water quality and water temperature directly affects the service life of the laser tube, it is recommended to use pure water and to control the water temperature below 35 ℃. For more than 35 ℃ to replace the circulating water, or to add ice to reduce the water temperature, water (cooling machine, suggest the user select or use two-tank).

Clean water tank: first, turn the power off and remove water inlet pipe, let the laser tube of water into the tank automatically, open the water tank, pump and clear the dirt on the water pump. Good clean water tank clean, replace the circulating water, the water pump to restore back into the water tank, the connection pipe inserted into the inlet of the pump, tidy up the joint. The pump power alone, and run 2 to 3 minutes (the laser tube is full of circulating water).

2. The cleanness of the fan

After long time use, it can make the fan inside the accumulation of a lot of solid dust, let the fan make a big noise, in addition to flavor and is unfavorable to the exhaust. When appear insufficient suction fan smoke not free, turn off the power supply first, will be discharged into the duct and the duct on the fan, remove the inside of the dust, and then put the fan on, and pull out the inside of the blades, until clean, then put the fan installed. Then it can support the co2 laser machine well working.

3. The lens cleaning (advice before work every day, clean equipment was turned off)

Machine is introduced in front, has talked about carving machine has three pieces of reflector and 1 piece of focusing mirror (1 reflector in the laser tube, the launch of the exit is at the upper left of the machine, the reflector is in the left side of the beam’s # 2 and # 3 mirrors in laser head on top of the fixed part, is located in the lower part of the laser focusing mirror adjustable lens barrel), after focusing laser is through the lens reflex, emitted from a laser. Lenses can easily touch dirt or other contaminants, cause loss or damage of lens of laser, no. 1 and no. 2 don’t must be removed, while the lens cleaning need to dip in cleaning fluid to clean lens paper carefully wipe up along one edge of the lens central to rotary. No. 3, lens and focus lens from the frame, in the same way, to wipe, wipe after the completion of the same back then.

Note: (1) The lens should be wiped gently, do not damage the surface coating;

(2) Should take put down gently wipe process, prevent fall;

(3) Focus lens installation please be sure to keep the concave downward.

Winter maintenance of CO2 laser cutting machine

- By a carbon dioxide laser tube, it is water-cooled, we had better control the temperature 25 degrees, because at this temperature when the energy of the strongest. In fact, the anti-high temperature in summer and freezing in winter are important.

- During the winter freeze, without the use of a laser engraving machine, if the water did not put the laser tube clean ice layer can cause cooling laser tube expansion, split up the laser cooling layer, resulting in the laser tube does not work. The winter laser tube cooling layer of the cracking is not within the scope of replacement. In order to avoid unnecessary losses, please follow our recommendations do it.

- How to freezing measures: Keep all laser cutting machine is powered off.

First, the laser tube of water put a clean thoroughly with an air pump or compressor (small volume less than 0.3MP) and other auxiliary equipment. Thoroughly clean and then put water pipes inside the laser machine-related.

Customers using chiller or pump, chiller or can be placed in a high temperature to remove the pump room, in order to prevent water circulation device freeze, causing damage to the chiller water pump parts to bring you unnecessary trouble; or the chiller water or put a clean pump inside thoroughly.

Another point to note is to do not add antifreeze in the laser tube inside, the antifreeze will affect the quality of light, the impact of heat, heat is not good, power and service life may be affected.

If you can afford to put the unit in a constant temperature environment.

Re-use, please do not open the water immediately after the laser work, wait for about 20 degrees and then back on to the water cycle laser, to prevent excessive temperature difference caused by the laser tube burst, causing you unnecessary losses.

Don’t try to open the chiller, it has been running in the device or when not in use, there are many security risks.

Be sure to check whether the water is done after each member as well as the residual water, residual water can also cause damage to related components, try to put a clean thoroughly to avoid unnecessary losses.