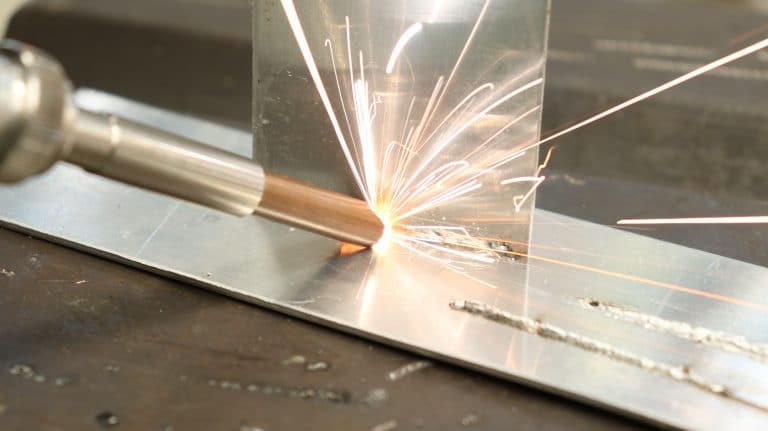

Today, MORN is pleased to introduce Metal Laser Cutting Machine with 12kW of Fiber Power, celebrating the coming 70th anniversary of the founding of the People’s Republic of China and MORN’s 19th Anniversary.

Table of Contents

Upgrade Technology to Inspire the Intelligent Manufacturing

The introduction of 12kW metal laser cutting machine marks that MORN has opened a new era of laser intelligent manufacturing. It achieves breakthroughs in cutting efficiency and speed, thickness: fine cutting of carbon steel and stainless steel 50MM, high-speed cutting of 900 small circles per minute, easily challenge the cutting of various metal materials, and the cutting efficiency is greatly improved. This 12kW has following advantages:

Advantage 1: Cutting thickness is greatly increased

The 12kw fiber laser has a good cutting section with a cutting limit thickness of 40mm or more, carbon steel of 50mm, and. Compared with the lower power laser, the improvement of the cutting ability has a great qualitative leap, which has greatly improved the processing range of the laser cutting machine.

Advantage 2: Great improvement in cutting speed

The cutting speed of different materials is a key factor in the selection of the power of the laser cutting equipment. Fiber laser cutting applications have significant advantages in medium and low thickness sheet processing, and the increase in laser power allows the cutting speed to be increased at a multiple speed.

The increase in speed brings about an exponential rise in the economics of fiber laser cutting machines. Especially for medium-thickness materials with fiber cutting, the cutting speed can be increased by more than 2 times.

Advantage 3: Increased diversity of cutting processes

High-power high-speed bright-surface cutting technology (HHB, High power, Highspeed, Bright surface), which uses high-power lasers to cut carbon steel sheets of different thickness at high speed with small nozzles, small air pressure, and high-power laser to obtain smooth cutting. Section and smaller machining taper. The smooth cutting surface facilitates the customer’s subsequent processing; at the same time, the taper can be controlled to be less than 0.2mm on both sides, and in some processing industries with high precision requirements, it can better meet customer requirements.

Thick plate cutting technology

Under the extension of high-speed glossy cutting technology, we have developed a small hole cutting technology for thick plates, which can cut high-quality small holes with a diameter much smaller than the thickness of the plate, for example, on a 20mm carbon steel plate.

A small hole with a diameter of 3-5 mm is cut and stable processing is possible.

Tips for high-speed shining cutting process

With the continuous development of fiber laser technology, the market demand for fiber laser cutting is getting higher and higher. Among them, the high-speed bright surface cutting process of carbon steel materials has been increasingly sought after.

So how to achieve a fast and good carbon steel shining surface cutting? The MORN process engineer shares with you the three cutting conditions that must be met:

Small nozzle: double nozzle, between 1.0-2.0mm;

High power: the higher the power, the greater the limit thickness of the carbon steel that can be cut, and the efficiency will be significantly improved;

Atmospheric pressure: mostly between 0.6-1.2Bar

In actual operation, not only need to meet these conditions but also need professional debugging, in order to achieve a consistent and consistent effect, MORN engineers can provide you with professional technical support for free.

Go Forward and Keep Improving

In recent years, MORN laser has continuously strengthened patent and technology innovation, and its products are constantly updated to meet the needs of domestic and foreign markets.

Focusing on the current situation of demand for the experience and personalization of the sheet metal processing industry and laser smart equipment, and the different aspects of user use and new generation equipment upgrade cutting effect, MORN will bring a better experience to the performance and production results of high-power laser smart equipment for industry users.

General manager Mr. Astone said: “In the Chinese laser sheet metal equipment industry,

East China, as an important application market, has important significance for laser equipment enterprises. It has always been the main front of laser intelligent equipment and application companies. MORN Laser is willing to develop together with the upstream and downstream of the industry to open up new prospects for China’s laser manufacturing business.”

The introduction of MORN laser 12000W metal laser cutting machine is of great significance to the enterprise itself. It is another important breakthrough of MORN in the high-power cutting market, and it also has important significance in the sheet metal industry.

Providing the sheet metal industry with more processing options and higher processing efficiency options.

The popularization and promotion of high-power cutting technology is another major step for MORN and the masses of users to enter into intelligent manufacturing. In the future, MORN will continue to innovate with technology upgrades, go all the way and contribute more to the advanced equipment manufacturing industry in Shandong and even China.