Laser cutting has developed steadily over the past few years. This applies to the machines, but also to the requirements. At MORNLASER, we are one of the leading metal laser cutting machine manufacturers for laser cutting, which is also known as laser beam cutting.

We have specialized in high quality laser cutting for everything to do with sheet metal processing. If you need help with 2D laser cutting of sheet metal, we will be happy to do this for you.

We can also help you with laser cutting of tubes with the corresponding 3D technology or with laser cutting of tubes with innovative fiber technology with experience, specialist knowledge and modern machinery. Our highly trained employees are the point of contact for these 3 common types of laser cutting.

Table of Contents

Laser cutting of sheet metal in 2D

A popular method for processing sheet metal is 2D laser cutting. This is an industrial process with which a laser beam is cut through the surface of the sheet metal. 2D laser cutting consists of the actual laser unit and the holder for the material.

Depending on the dimension and implementation, the workpiece or, alternatively, the laser unit is shifted in two dimensions. The laser cutting of sheet metal is characterized by the fact that the control is quite simple. The axes are usually moved staggered in time. Alternatively, the control can also be implemented synchronously.

The 2D laser cutting can be done via the computer control. The measurement is carried out with the help of sensors and as soon as the comparison between the actual and target state is done, the laser beam generates high energy and the sheet is melted. We do 2D laser cutting quickly, reliably, professionally and on fair terms.

ADVANTAGES OF 2D LASER CUTTING

If you decide to use 2D laser cutting and commission us, you will benefit from a number of convenience. We use the most modern technologies and a modern fleet of machines.

In this way, we can reduce production costs while maintaining the same high quality, process different strengths and sizes with great precision, and there is no longer any need for intermediate storage.

Furthermore, 2D laser cutting enables the advantages that the manufacturing steps are enormously simplified, the effort for assembly is lower and the delivery times are shorter. We at Kovinc can offer you a fair and attractive price-performance ratio. We are your contact when it comes to laser cutting sheet metal in 2D.

Laser cutting of pipes with 3D technology

When it comes to machining pipes, there are several options. Above all, 3D laser cutting is in demand. This technology is primarily used in the metal processing industry and has developed into one of the leading manufacturing processes.

This is an innovative technology with which three-dimensional workpieces, in the case of tubes, can be processed. When 3D tube laser cutting various technologies are used – among other things, the actual laser technology and the mechanical control.

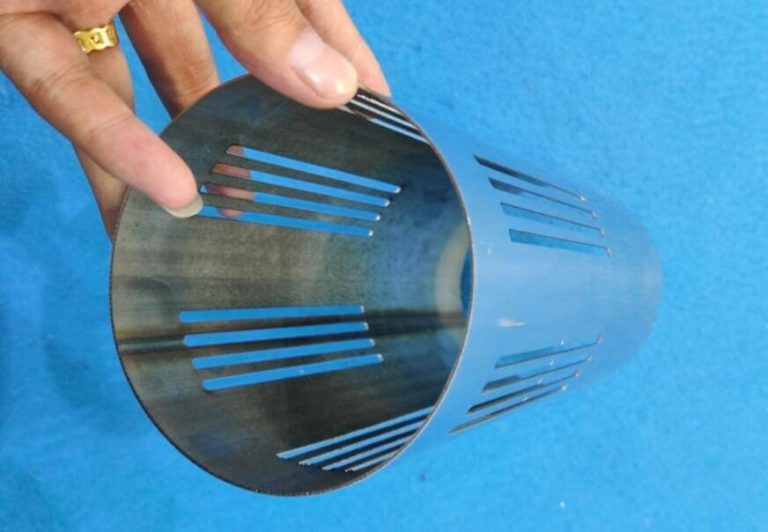

But also the supply, removal and the actual movement of the workpieces are based on innovative technologies. 3D laser cutting can cut out individual contours and cutouts from the tubes. Technically, this type of tube processing is convincing with its significantly higher economic efficiency and first-class quality precision.

ADVANTAGES OVER OTHER METHODS

If you have relied on manual processes in production up to now, the 3D process is like a revolution. We at MORNLASER recognized this early on and thus significantly increased our competitiveness.

3D laser cutting is associated with lower costs and the quality is much higher. The work steps are carried out faster, the follow-up controls are less time-consuming and post-processing is usually no longer necessary.

In addition, the time phase from design to delivery is shorter. So you can see that this manufacturing process brings a number of conveniences, especially compared to manual processes.

Laser cutting of tubes with fiber technology

The laser cutting of tubes with fiber technology is used above all in mass production. This type of process is very modern and meets today’s requirements.

Accordingly, the solution is for fast, accurate and inexpensive machining of pipes. With fiber technology, we can process pipes with a maximum diameter of 120 mm.

We are just as flexible in terms of weight and can even move pipes with a maximum of 13.5 kg / m. Modern fiber technology has many advantages and consumes less electricity, especially compared to other types of processes. As an environmentally conscious company, this is an invaluable advantage.

THE OTHER ADVANTAGES

Further advantages of laser cutting with fiber technology are the precise processing and the significantly shorter processing times. Fiber technology cutting is the ultimate solution, especially for large-scale production.

What sets us apart at MORNLASER in general

At MORNLASER, we are one of the leading metal laser cutting machine manufacturers in the field of metalworking. Our team of reliable employees has a lot of experience and in-depth knowledge.

We have all the important certificates (ISO 9001, EN 1090, ISO 3834-2) and carry out all orders exactly according to your customer requirements. If you are looking for a reliable partner in the metal processing industry, welcome talk to us now through chatbox.