The reasonable selection of welding methods and processes in the power battery manufacturing process will directly affect the cost, quality, safety and consistency of the battery. Next, I will sort out the content of power battery welding.

Table of Contents

1 Principle of laser welding

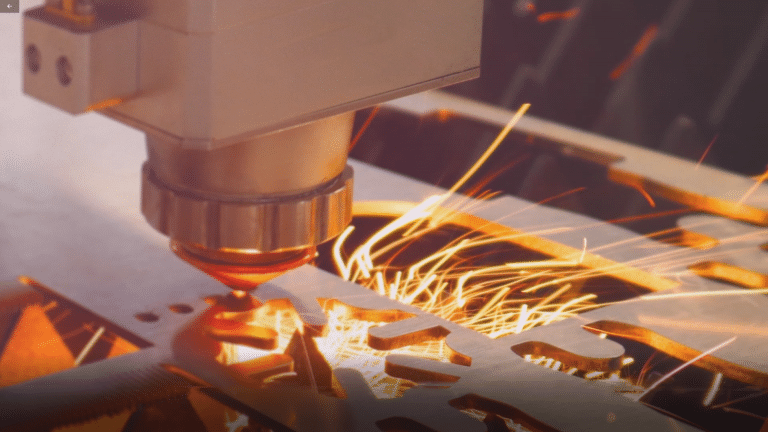

Laser welding uses the excellent directivity and high power density of the laser beam to work. The laser beam is focused in a small area through the optical system, so that the welded area forms a highly concentrated heat source in a very short time. Zone, so that the welded object melts and forms a firm solder joint and weld.

2 Laser welding type

Heat conduction welding and deep penetration welding

In heat conduction welding, the laser beam will melt on the surface of the workpiece along the joint, and the melt will flow together and solidify to form a weld. Mainly used for relatively thin materials, the maximum welding depth of the material is restricted by its thermal conductivity, and the width of the weld is always greater than the welding depth.

In deep penetration welding, when the high-power laser is concentrated on the metal surface, the heat is too late to dissipate, and the welding depth will be sharply deepened. This welding technology is deep penetration welding. Because the deep penetration welding technology has a very fast processing speed, a small heat-affected area, and minimizes distortion, this technology can be used for deep welding or welding of several layers of materials.

The main difference between thermal conduction welding and deep penetration welding is the power density applied to the metal surface per unit time, and the lower critical value is different for different metals.

Through welding and seam welding

Through welding, the connecting piece does not need to be punched, and the processing is relatively simple. Penetration welding requires a laser welder with higher power. The penetration depth of penetration welding is lower than that of seam welding, and the reliability is relatively poor.

Compared with penetration welding, seam welding requires less power laser welding machine. The penetration depth of seam welding is higher than that of penetration welding, and the reliability is relatively good. However, the connecting piece needs to be punched, which is relatively difficult to process.

Pulse welding and continuous welding

1) Pulse mode welding

The appropriate welding waveform should be selected when laser welding. Commonly used pulse waveforms include square wave, peak wave, double peak wave, etc. The reflectivity of the aluminum alloy surface to light is too high. When the high-intensity laser beam hits the material surface, the metal surface will 60%-98% of the laser energy is lost due to reflection, and the reflectivity varies with surface temperature. Generally, sharp wave and double peak wave are the best choice when welding aluminum alloy. The slow-down part behind this welding waveform has a longer pulse width, which can effectively reduce the generation of pores and cracks.

Pulse laser welding samples

Due to the high reflectivity of aluminum alloy to laser, in order to prevent the vertical reflection of the laser beam from vertical incidence and damage the laser focusing mirror, the welding head is usually deflected to a certain angle during the welding process. The diameter of the solder joint and the effective joint surface increases with the increase of the laser tilt angle. When the laser tilt angle is 40°, the largest solder joint and effective joint surface are obtained. The welding point penetration and effective penetration decrease with the laser tilt angle. When it is greater than 60°, the effective welding penetration decreases to zero. Therefore, tilting the welding head to a certain angle can appropriately increase the weld penetration and width.

In addition, when welding, with the welding seam as the boundary, 65% of the laser welding spot offset from the cover plate and 35% of the shell must be welded, which can effectively reduce the explosion caused by the cover problem.

2) Continuous mode welding

Since continuous laser welding is not heated like a pulse machine, the tendency of cracks is not obvious during welding. In order to improve the quality of the weld, continuous laser welding is used. The surface of the weld is smooth and uniform, without spatter, defect, and inside the weld. No cracks were found. In the welding of aluminum alloys, continuous lasers have obvious advantages. Compared with traditional welding methods, the production efficiency is high and no wire is required. Compared with pulsed laser welding, it can solve the defects generated after welding, such as cracks, Porosity, spatter, etc., ensure that the aluminum alloy has good mechanical properties after welding; it will not sag after welding, and the amount of polishing and grinding after welding is reduced, which saves production costs. However, because the continuous laser spot is relatively small, the assembly accuracy of the workpiece is The requirements are higher.

Continuous laser welding samples

In power battery welding, the welding process technicians will select the appropriate laser and welding process parameters according to the customer’s battery material, shape, thickness, and tensile requirements, including welding speed, waveform, peak value, welding head tilt angle, etc. to set reasonable Welding process parameters to ensure that the final welding effect meets the requirements of power battery manufacturers.