Table of Contents

New Web Celebrity in laser welding field — The development of Handheld laser welding

In recent years, there have been a lot of popular people on the Internet, with countless fans, speaking, known as “Web Celebrity”, and these two years to say in the laser welding industry web celebrity that is “Hand-held laser continuous welding machine”! So today I’m going to show you how hard it has been for this Web Celebrity product.

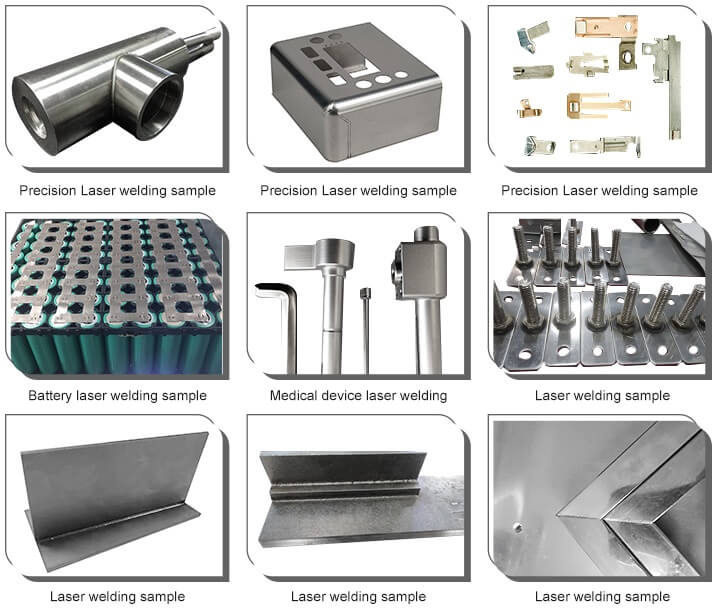

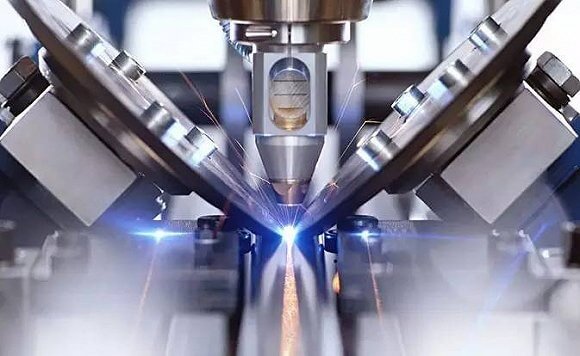

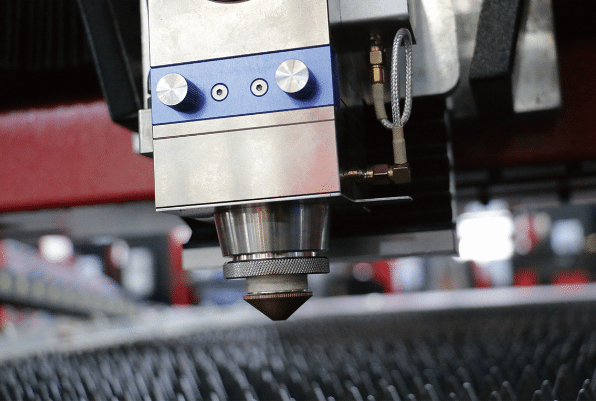

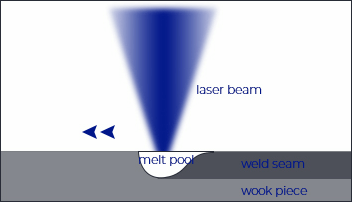

Laser welding uses a high energy density laser beam as a heat source for efficient precision welding. Since laser welding requires high precision for work-piece pre-machining, the position of the beam on the work-piece is not significantly offset. If the assembly accuracy or beam positioning accuracy of the work-piece does not meet the requirements, it is easy to cause welding defects, which limits the process capability of laser welding to a certain extent. This is because the spot size is small and the weld is narrow after laser focusing.

More than ten years ago, the main laser used for laser welding in China was the solid-state lamp pumped laser, which had a large energy consumption and a large volume. In order to solve the shortcomings such as the difficulty in changing the direction of the optical path, optical fiber transmission laser welding equipment was introduced. Then inspired by the foreign Handheld optical fiber transmission equipment, produced their own Handheld laser welding machine.

This is the “first generation of Handheld laser welding machine” in China. Due to the flexible transmission of optical fiber, the operation convenience of welding equipment has been greatly improved.

Which was better then, the “first generation Handheld laser welder” or TIG welder?

That’s what people like to ask. In fact, strictly speaking, this is two types of equipment, working on different principles, can not be simply compared, can only say that they have their respective applicable occasions. Here’s a look at where each applies.

Manual TIG welding advantages:

- Low price and small size;

- Suitable for welding of materials over 1 mm;

- High welding strength, suitable for most materials;

Manual TIG welding disadvantages:

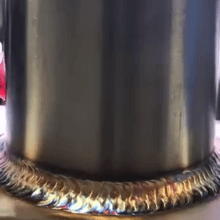

- The heat affected area is large, which is easy to produce deformation;

- Easy to produce defectsfor plates below 1mm;

- Arc light and waste smoke are harmful to human body.

Therefore, manual TIG welding is more suitable for medium thickness plate welding and welding of structural parts with certain strength requirements. If you want to get a right-angle welding seam at the edges and corners of thin plate welding, the later polishing work will be large, and it is easy to produce welding defects.

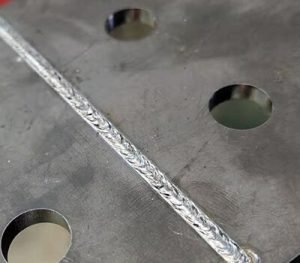

Advantages of the first generation Handheld laser welding machine:

- Fine spot, adjustable between 0.6-2mm.

- Low calorific value is not easy to produce deformation.

- Less polishing in later stage.

- No large amount of waste smoke will be produced.

Disadvantages of the first generation Handheld laser welding machine:

- The price cost is relatively high.

- Large volume and high energy consumption. The volume is about two cubic meters, and the energy consumption is about 6 degrees per hour in terms of 200 watts of power used.

- The depth of melting and welding strength is not very high. The welding power is still 200 W, and the depth of penetration is about 0.3 mm when the spot is 0.6 mm.

Therefore, the first generation of hand-held laser welding machine just fills the shortcoming of argon arc welding, which is more suitable for the products with thin sheet materials and low welding strength requirements. The appearance of welding is beautiful and easy to polish. Widely used in advertising welding, grinding tool repair and other industries. But the high price, high energy consumption and huge volume still prevent it from being widely promoted and applied.

A: So will the device never get any better?

B: Apparently not.

In 2017, with the rise of domestic laser enterprises, the domestic high-performance fiber laser has been promoted. Fiber laser have launched 500 W, 1000 W and 2000 W and other medium and high power lasers. Fiber laser quickly occupies the market with the characteristics of good beam quality, small volume, small energy consumption and good equipment stability and compatibility, so that laser processing also has a larger market share, and quickly replace the previous lamp pumped solid laser. At this time, some people found a business opportunity, among which the laser equipment manufacturing enterprises represented by MORN Laser took the lead to launch a hand-held optical fiber laser welding machine with 500 W optical fiber laser as the light source, which can be said to be the “second generation of Handheld laser welding machine”.

How does the second generation compare to the first?