Table of Contents

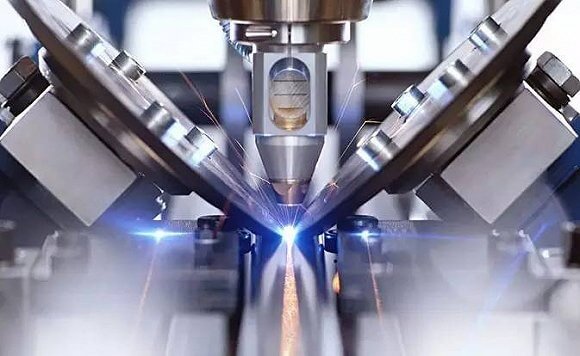

Nine Standards to Test Cutting Quality of Fiber Laser Cutting Machines

How to tell the quality of a fiber laser cutting machine when purchasing, the following 9 standards are indispensable:

Roughness

After cutting, fiber laser cutting machine will form vertical lines in section. The depth of the lines determines the roughness of the cut surface. The shallower the lines, the smoother the cut section. Roughness not only affects the appearance of the edge, but also affects the friction characteristics. In most cases, it is necessary to minimize the roughness, so the shallower the texture, the higher the cutting quality.

Verticality

If the thickness of the sheet metal exceeds 10mm, the verticality of the cutting edge is very important. When away from the focus, the laser beam becomes divergent, and depending on the position of the focus, the cut becomes wider toward the top or bottom. The cutting edge deviates from the vertical line by a few hundredths of a millimeter. The more vertical the edge, the higher the cutting quality.

Cutting width

Generally speaking, the cutting width does not affect laser cutting quality. The cutting width has an important effect only when a particularly precise contour is formed inside the component. This is because the cutting width determines the minimum inner warp of the contour. When the thickness of the sheet increases, the cutting width also changes. The increase. Therefore, in order to ensure the same high precision, no matter how large the width of the cut, the workpiece in the processing area of the laser cutting machine should be constant.

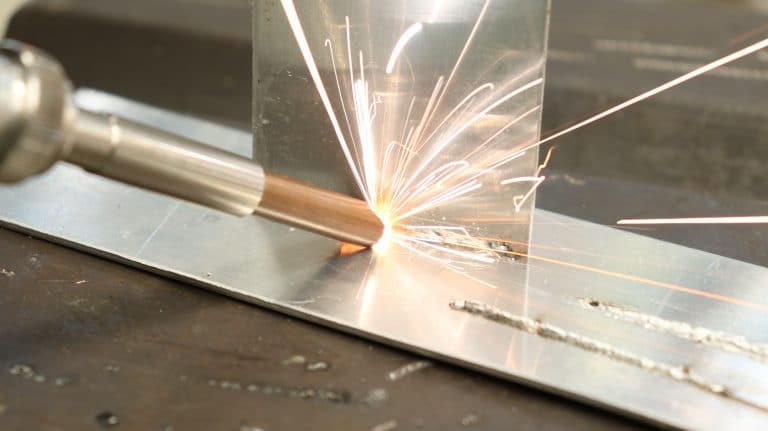

Texture

When cutting thick plates at high speed, the molten metal will not appear in the incision below the vertical laser beam, but will spray out at the rear of the laser beam. As a result, curved lines are formed on the cutting edge, and the lines closely follow the moving laser beam. In order to correct this problem, reducing the feed rate at the end of the cutting process can greatly eliminate the formation of lines.

Burr

The formation of burrs is a very important factor that determines the quality of laser cutting. Because the removal of burrs requires extra work, the severity and amount of burrs can intuitively judge the quality of the cutting.

Material deposition

The laser cutting machine first hits a layer of special oily liquid on the surface of the workpiece before melting and perforating. During the cutting process, due to gasification and various materials are not used, the customer uses wind to remove the incision, but the upward or downward discharge will also form a deposit on the surface.

Depression and corrosion

Concavity and corrosion have an adverse effect on the surface of the cut edge and affect the appearance. They appear in cutting errors that should generally be avoided.

Heat affected zone

In laser cutting, the area around the incision is heated. At the same time, the structure of the metal changes. For example, some metals will harden. The heat-affected zone refers to the depth of the area where the internal structure changes.

Deformation

If the cutting heats the part sharply, it will deform. This is especially important in fine machining, because the contours and connecting pieces here are usually only a few tenths of a millimeter wide. Controlling the laser power and using short laser pulses can reduce parts heating and avoid deformation.

As laser manufacturer, MORN Laser has been dedicatedto the application of laser equipment in various industries and providing customers with the most suitable complete industry solutions. You’re welcome to inquire, visit and make samples. We look forward to your visit: www.morntech.com