How much is a fiber laser cutting machine? I believe many buyers in the early inquiry stage have found that not only the price varies greatly between different models, the price gap between manufacturers is also very large. The inexpensive fiber laser cutting machine can be tens of thousands of dollars, whereas the expensive fiber laser cutting machine may cost hundreds of thousands of dollars.

Then what factors cause the price gap of a fiber laser cutting machine to be so large?

Today we will figure out the secrets behind the price gaps.

To find the reasons cause the price gap, we should first know the main factors that determine the pricing of a fiber laser cutting machine.

Table of Contents

Core Part That Costs the Most

The fiber laser cutting machine is currently the most flexible processing equipment in metal cutting. It performs undisputed superior quality cutting on various metal materials, including stainless steel, carbon steel, brass, and aluminum, etc. Thus it is also known as a metal laser cutting machine or laser metal cutting machine.

Generally, the heart of a metal laser cutting machine, fiber laser generator, is the most expensive core part. The higher the laser power, the higher the price of the laser cutting machine. The price gap is huge if you make a comparison between a 1000W fiber laser cutting machine and a 6000W fiber laser cutting machine.

What’s more, the price of the laser generator also varies greatly between brands. For instance, the most popular fiber laser generators among Chinese metal laser cutting machine manufacturers are IPG, Raycus, and Max. The price is also of great difference. The IPG laser that widely used for cutting reflective metals, costs almost double that of Raycus or Max. Whereas the latter stands out for cost-effectiveness.

Different brands of laser generators have different effects, but the difference in cutting thickness is basically not big.

When purchasing fiber laser cutting machines, buyers should better choose the suitable laser power according to their actual cutting tasks, such as the metal to be cut and its thickness.

Another relatively expensive part of the fiber laser cutting machine is the cutting head. Some manufacturers adopt original Switzerland Raytools Cutting Head, while others use their own brand laser cutting head. This also makes a difference in the price of the fiber laser cutting machine. When coming across the so-called own brand cutting head, be sure to check how long they have been doing in this field and investigate whether they are really producing them or outsourcing those parts and then put a brand on it. Because this will lead to the price difference, but more quality difference.

According to the shapes of processing metals, the metal laser cutting machine can be classified into sheet metal laser cutting machine, tube/pipe laser cutting machine and dual-use(Sheet and tube) laser cutting machine. Obviously, a dual-purpose fiber laser cutting machine costs higher than a single purpose one.

Regarding the format of cutting pallet, there is no need to blindly pursue a large format. Different formats also mean different costs. Considering the ROI, it is recommended to select a cutting format that fits 80% of your frequently cutting materials. Furthermore, large format is not necessarily good, and some low-quality low-quality machines have unstable average laser output at various points on the large format.

In short, just like a computer, a fiber laser cutting machine is composed of multiple parts, with different configurations such as laser power and laser cutting head, prices vary accordingly. It must be comprehensively evaluated based on demand.

Price Gap Between Different Suppliers

- Brand premium

This is a long-term accumulation of word of mouth. The brand effect brings brand premium.

With the same configuration, the prices of Top brands will be relatively higher, and it is understandable. Such as mobile phone, iPhone is more expensive than others for the same memory.

2. Manufacturer strength

This often means product technology and quality. It is obvious that the more powerful companies have more funds, manpower and material resources for product research and development and technology upgrades. Their products are better in quality and prices are relatively high.

3. Service capabilities

Fiber laser cutting machine is a high-tech product. In the process of use, due to improper use, working environment or long-term shutdown factors, some malfunctions may occur. Therefore, after-sales service is a must when choosing fiber laser cutting machines.

Generally speaking, the after-sales service of large companies is guaranteed with nationwide technical support and after-sales service system. Small companies may have a discount on after-sales services due to capital cost considerations. Be careful when making the final decision on your fiber laser cutting machine.

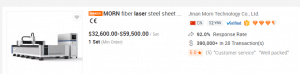

Investigate the export or manufacturing experience of a Chinese laser cutting machine company on Alibaba.

Conclusion

In a nutshell, how much is a fiber laser cutting machine? In fact, there is no standard answer. There are many factors that affect the price of fiber laser cutting machines, and comprehensive evaluation is required. More importantly, you should choose a fiber laser cutting machine that meets your own purpose.

Talk about your cutting purposes with MORN LASER via the online chatbox on the bottom right of the screen.