There will be some problems more or less during the use of laser cutting machine. Of course, any machine has the possibility of failure. In order to make the cutting work better, reduce the failure rate, and improve work efficiency, we must understand the working principle of the laser cutting machine. The following are common faults and treatment methods of laser cutting machine:

Table of Contents

1. There is no response after booting

▶Whether the power fuse is burned out: replace the fuse.

▶Whether the power input is normal: Check the power input and make it normal.

▶Whether the main power switch is damaged: replace the main power switch.

2. No laser output or weak laser

▶Whether the light path is offset: carefully adjust the light path.

▶Whether the reflective lens is dirty or damaged: Clean or replace the reflective lens.

▶Whether the focal length of the device has changed: re-adjust the focal length.

▶Whether the focusing lens is dirty: clean the focusing lens.

▶Whether the cooling water quality or water temperature is normal: replace the clean cooling water to bring the temperature to normal value.

▶Whether the cooling water is circulating: clear the cooling water circuit.

▶Whether the laser tube is damaged or aging: replace the laser tube.

▶Whether the laser power supply is energized: check the laser power supply circuit to make it normal.

▶Whether the temperature of the whole machine is too high: 1. Shut down and let the temperature drop; 2. Ventilate to enhance the heat dissipation of the machine; 3. Adjust the ambient temperature.

▶Whether the laser power supply is damaged: replace the laser power supply.

3. The cutting/engraving depth is not ideal

▶Whether the cutting/engraving processing parameters are normal: Set appropriate processing parameters.

▶Is the laser power setting normal: set the laser power correctly.

▶Laser output becomes weak: see point 2.

4. The computer and the device are not connected

▶Whether the scan switch is turned on: Turn on the scan switch.

▶Whether the motion system is powered on: Check the power supply of the motion system and make it normal.

▶Whether the DSP motion control card is damaged: replace the DSP motion control card.

▶Whether the signal wire is loose: reinsert the signal wire plug and fix it.

5. The processing size has errors or movement errors

▶Whether the whole machine and the computer are properly grounded: ground the equipment and the computer well.

▶Whether the signal line is normal: replace the signal line.

▶Computer operating system failure or virus infection: reinstall the operating system or disinfect.

▶Whether the computer is operating normally: replace or dispose of the computer.

▶The power supply is unstable or has interference signals: install a voltage stabilizer or eliminate interference signals.

▶Whether the application software is normal: reinstall the software and the driver software of the motion control card.

▶Whether the processing parameters are set correctly (such as layout, etc.): reset the corresponding parameters

▶Whether the processing program is written normally: check the processing program and modify it until it is normal.

6. The slider movement is not ideal

▶Whether the carriage slides and sliders are dirty: Clean the slides and sliders.

▶Whether the guide rail is dirty: clean the guide rail and add lubricant.

▶Whether the transmission gear is loose: tighten the transmission gear

▶Whether the drive belt is loose: Adjust the belt tightness.

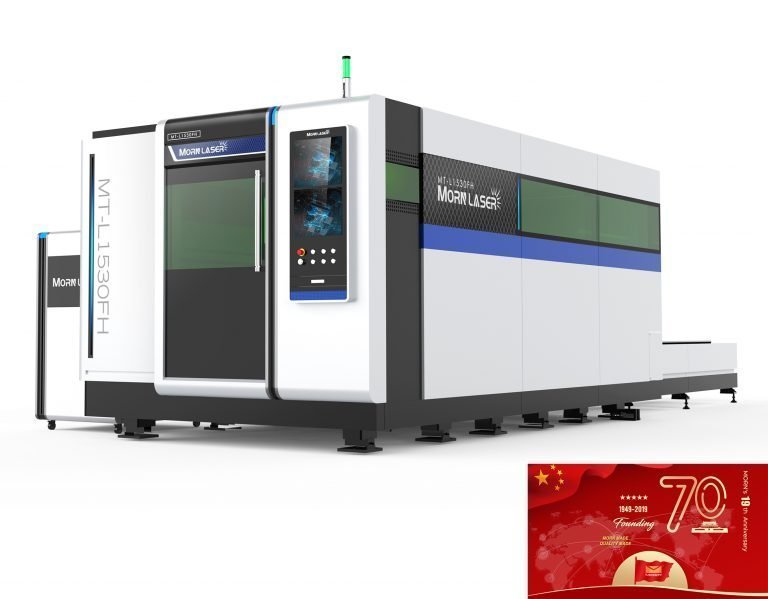

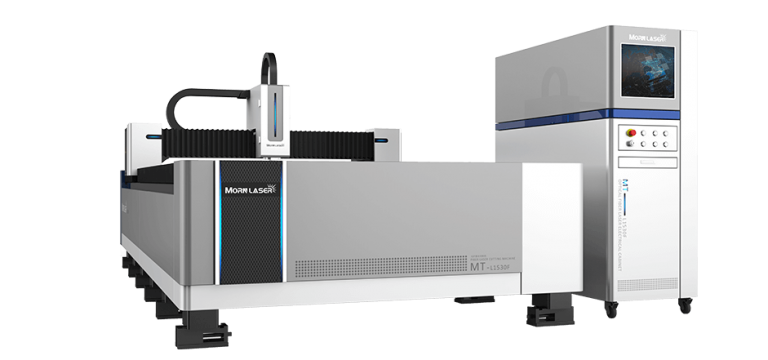

7. MORN LASER

MORN Laser was established in 2008 and has more than ten years of production and export experience. With accumulated technology and guaranteed quality, we can provide customers with the best solutions. MORN laser accessories are all original products. We always take “Quality is Social Responsibility” as our corporate purpose, and constantly research better cutting solutions.

Our main products are fiber laser cutting machine, fiber laser welding machine, fiber laser marking machine, finer laser cleaning machine, etc. MORN laser is waiting for you!