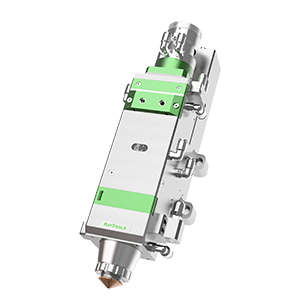

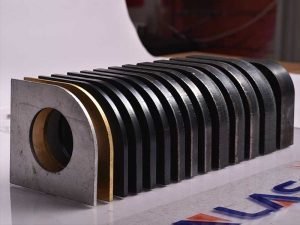

IPG/Raycus Laser Source

• 100,000 hours of lifetime, free maintenance;

• High electro-optical conversion efficiency (up to 25-30%), excellent beam quality, high energy density, and reliability, a wide modulation frequency;

• Low energy consumption, only 20%-30% of the traditional CO2 machine

Contact Us

Previous

Next