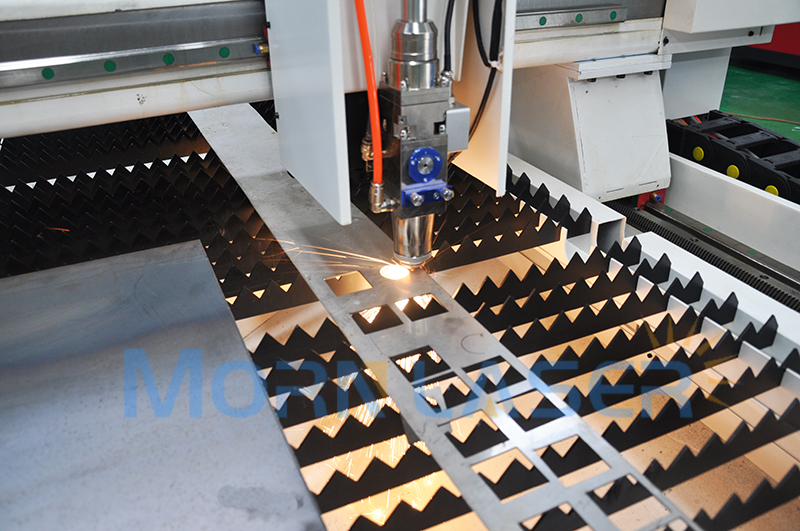

Fiber laser cutting system produces a fine continuous laser beam that make it possible for these lasers to be used to cut small components with a high degree of accuracy. When coupled with a CNC controlled manipulator, a fiber laser can manufacture small components suitable for use in precision machinery, jewelry, instruments and electronics.

This ability makes precision laser cutting applications a viable alternative to miniature mechanical precision turning and machining equipment.

A fiber laser system is a solid-state laser that produces a narrow beam with a very high intensity. The laser can be operated in continuous mode and this ability improves the quality of the surface finish on the final component. The laser has the ability to cut thin materials at high linear speeds. It has a compact design and does not require complex optics. Fiber lasers are very stable and have low maintenance requirements.

Table of Contents

1. Materials That Can Be Cut

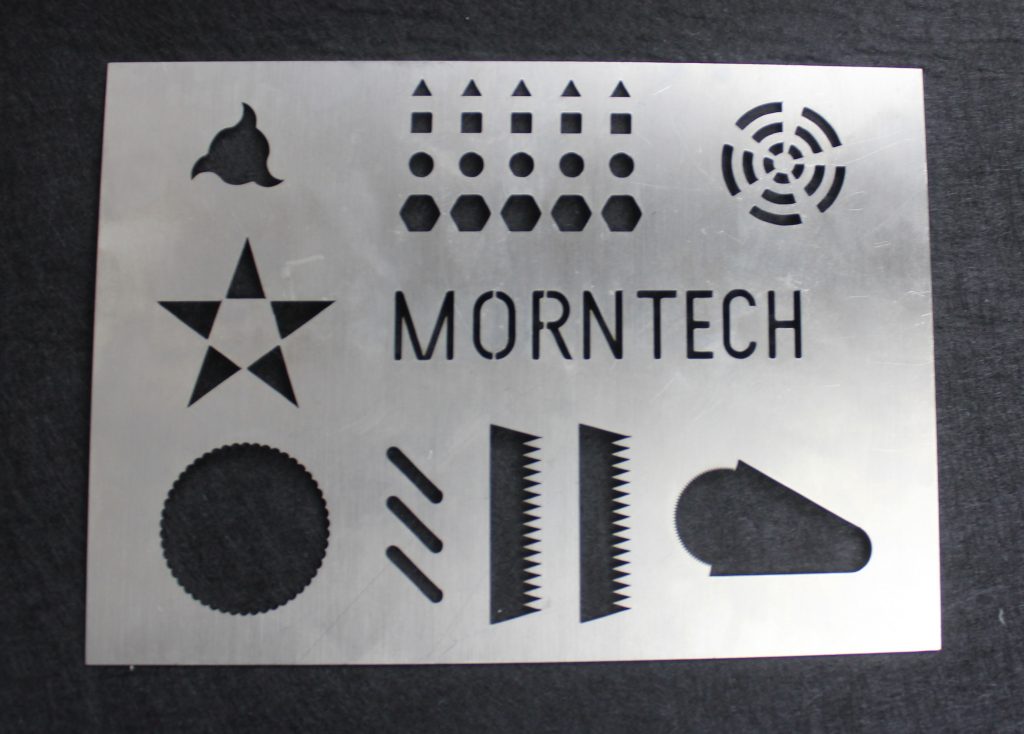

The intense narrow light beam of a fiber laser allows it to cut materials that are usually difficult to cut with conventional laser systems. These include highly reflective metals such as copper, precious metals such as silver and gold, ceramics and plastics. Other materials that can be cut include mild steel, high strength steels, stainless steel, titanium, and platinum.

2. High Tolerances

The fiber laser cutting machine is capable of achieving an accuracy of one thousandths of an inch (0.02mm). The continuous nature of the light beam eliminates the slight roughness often apparent with pulsed lasers and requires no maintenance or adjustment, which ensures repeatability. The 4-axis motion control mechanism uses servo motors for positioning and has a reticulating ball transmission that’s adjustable to eliminate mechanical play.

It’s important to note that tolerances for laser cutting applications are affected by material softness and melting point, especially when processing softer precious metals.

3. Productivity

Although the fiber laser metal cutting machine has the ability to cut and machine to tight tolerances, productivity is high as the laser is capable of cutting at speeds of up to 8 inches per second (200mm/s). Overall productivity depends upon the thickness of the material being cut, its characteristics, and the complexity of the cut required.

4. Specialized Applications

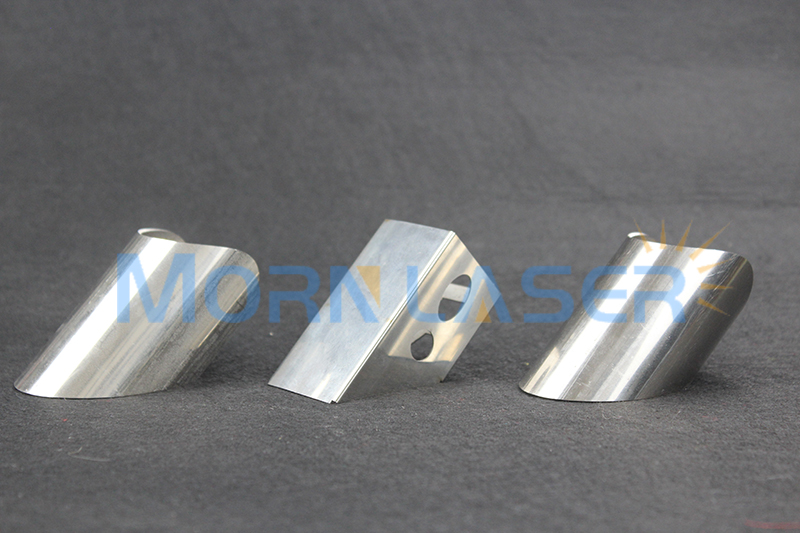

Laser cutting and machining is the first step in the manufacture of complex components for many industries including the medical device, automotive, aerospace, jewelry and general manufacturing industries that require small and micro components.

Examples of component parts that can be produced include:

- Medical Devices: Various medical device and component parts crafted from titanium, platinum, and ceramics.

- Automotive: various component parts used in the assembly of automobiles.

- Electronics: Semi-Conductor chips.

- Watch and Clock Components: laser cutting can be used to make escapement wheels, shafts, and gears.

- Jewelry Manufacturing: monograms, necklaces, and earrings made with precious metals.

5. Almost Unlimited Opportunities

Fiber laser cutting applications open many avenues for complex machining and cutting of an almost unlimited variety of materials. Important characteristics such as the excellent finish, good edge detail, and extremely high tolerances create opportunities for cost-effective manufacture of parts and components that compare well with traditional methods.

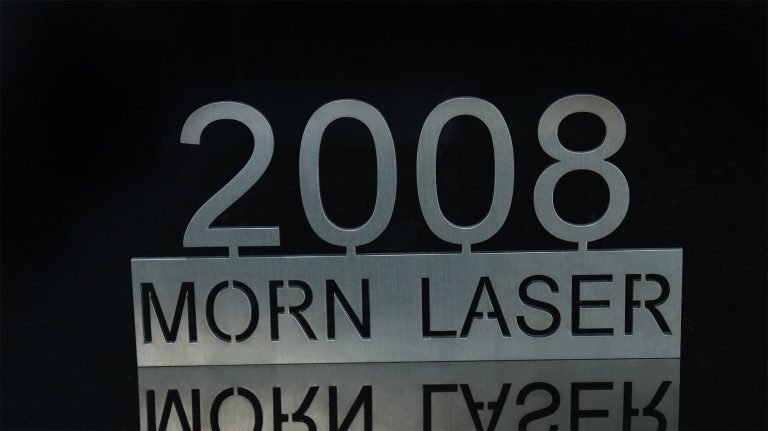

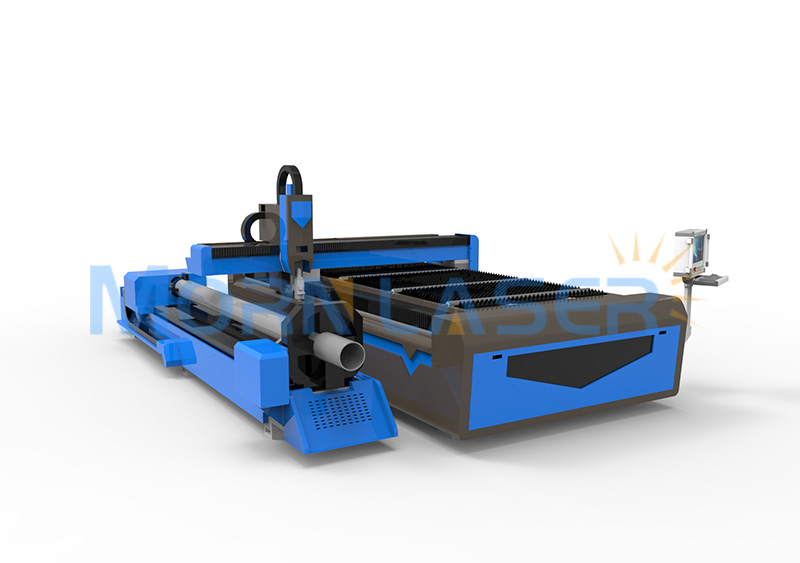

Contact MORN LASER team now to find out how fiber laser cutting machine for metals can reduce your costs and improve efficiencies in your manufacturing process. One of our applications specialists will help you develop the laser cutting system for you. We can help determine the appropriate laser source, beam delivery and cutting parameters. We can also help with fixture development, custom optical systems, control integration and the production of test pieces.